Chocolate remains one of the most popular confectionery products in the world. Consumers expect every bite to be smooth, creamy and consistent. For manufacturers, achieving this ideal texture requires precision in formulation and processing. One ingredient that has become central to this process is PGPR. Although used in very small quantities, PGPR plays a major role in improving chocolate flow, enhancing texture and supporting efficient large scale production.

This detailed article explores what PGPR is, why it is used, how it works inside chocolate formulations and why it has become an essential ingredient in modern chocolate manufacturing. It also highlights its safety profile and how global confectionery brands rely on it to improve product quality.

What is PGPR

PGPR stands for Polyglycerol Polyricinoleate. It is a specialty emulsifier widely used in the chocolate and confectionery industry. PGPR is produced from castor beans by combining polyglycerol with fatty acids derived from castor oil. The result is a functional ingredient with unique properties that influence the flow behavior of chocolate.

Chocolate contains several solid particles including cocoa solids, sugar and milk powder, all suspended in cocoa butter. These particles interact with each other and create resistance when the chocolate flows. PGPR reduces this resistance by lowering the friction between particles. This directly improves the flow of chocolate without requiring significant changes to the recipe.

PGPR is often used along with lecithin or partially replaces it to optimize the rheological characteristics of chocolate for industrial production.

Why PGPR Is Important in Chocolate Manufacturing

Chocolate is technically a suspension. For manufacturers, controlling its viscosity is essential. A chocolate that flows well will fill molds cleanly, coat products evenly and move through machinery without causing blockages.

Traditionally, manufacturers added extra cocoa butter to reduce viscosity. While effective, this increases production cost substantially because cocoa butter is one of the most expensive ingredients in chocolate making. PGPR provides a more economical solution without compromising quality.

PGPR surrounds solid particles in chocolate and reduces the forces that hold them together. Once this friction is reduced, the chocolate becomes more fluid and easier to process. This makes PGPR particularly useful in molding, pumping and enrobing applications where smooth and controlled flow is critical.

Modern production lines run at high speeds and require ingredients that help maintain consistency. PGPR supports this by ensuring the chocolate behaves predictably during every stage of manufacturing.

Benefits of PGPR in Confectionery Applications

Improved Flow and Reduced Viscosity

The most significant benefit of PGPR is its ability to reduce the yield stress of chocolate. Yield stress is the minimum force required to make chocolate start flowing. By lowering it, PGPR helps chocolate move easily through pumps, pipes and enrobing systems. This results in a more efficient and stable production process.

Uniform and Thin Coatings

PGPR is widely used in enrobing operations. When coating biscuits, wafers, ice creams or confectionery centers, manufacturers need chocolate that spreads evenly and forms a thin, glossy layer. PGPR allows this by improving flow at low fat levels and ensuring the coating dries with a clean, professional finish.

Lower Cocoa Butter Usage and Cost Savings

One of the biggest advantages for manufacturers is cost efficiency. Because PGPR improves flow even at reduced fat concentrations, manufacturers can use less cocoa butter while maintaining the same texture and performance. This reduces production costs without affecting product quality. Over time, the savings can be substantial, especially in high volume production.

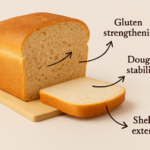

Enhanced Shelf Stability and Reduced Fat Bloom

Fat bloom is a common challenge in chocolate. It appears as a whitish layer on the surface caused by fat migration or improper crystallization. While harmless, it affects the appearance and consumer appeal of chocolate. Some studies indicate that PGPR can help improve the stability of fat crystals and reduce the possibility of fat bloom, supporting better shelf life and aesthetics.

Compatibility With Lecithin

Lecithin is another widely used emulsifier in chocolate. While lecithin reduces viscosity to a point, PGPR is more effective at lowering yield stress. When used together, they create a balanced system that allows manufacturers to fine tune flow behavior. This synergy is especially useful in premium chocolate and coating applications where precision is required.

Safety and Regulatory Approval

PGPR is approved for use in food across many countries. Regulatory bodies such as the United States Food and Drug Administration and the European Food Safety Authority have evaluated its safety and determined that PGPR is safe when used within recommended limits.

PGPR is plant derived, coming from castor bean oil. It does not affect the flavor of chocolate and is used in very low percentages, typically less than one percent of the total formulation. Its safety, stability and effectiveness have made it a trusted ingredient in global chocolate brands.

Consumers are increasingly interested in the origin and processing of food ingredients. PGPR’s plant based source supports clean formulation strategies and aligns well with the expectations of modern consumers.

Why PGPR Has Become a Standard Ingredient for Chocolate Makers

Chocolate processing has evolved significantly over the years. Modern production lines require precise rheology, consistent flow, reduced waste and minimal disruptions. PGPR supports all of these requirements.

Whether used in molded chocolates, compound coatings, high speed enrobing lines or bakery applications, PGPR delivers predictable performance and operational efficiency. Its ability to reduce cocoa butter usage also makes it an economically attractive ingredient for large scale manufacturers.

As demand for chocolate continues to grow globally, manufacturers look for reliable ways to improve both quality and productivity. PGPR has proven to be one of the most effective ingredients to achieve these goals, making it a standard in the industry.

Conclusion

PGPR plays a vital role in modern chocolate making. Although used in small amounts, it significantly improves chocolate texture, flow behavior and production efficiency. From lowering viscosity to enabling thin and uniform coatings, PGPR helps manufacturers produce high quality chocolate at scale. It also supports cost efficiency by reducing the need for cocoa butter and offers benefits related to shelf stability and processing control.

Chemtradex supplies high quality PGPR designed for chocolate, confectionery coatings and industrial food applications. Our products meet international standards and deliver consistent performance for modern manufacturing needs. For technical specifications, guidance on usage levels or sample requests, connect with the Chemtradex technical team.